When electronic or electrical equipment of any type is intended for use in a hazardous area, the equipment must be ATEX certified as required by the EU directive 94/9/EC. This directive is more commonly known as the ATEX directive (from the French: ATmospheres EXplosives). Within Europe ATEX certification of products for use in potentially hazardous atmospheres is compulsory.

Hazardous areas exist where a potentially explosive mix of air and flammable gasses or air and dust or air, dust and gasses may occur. You can find all of our ATEX approved products suitable for hazardous areas on our website.

Outside of the European Union similar regulations apply under the IECEX certification system. In North America products must be listed by UL as suitable for use in hazardous atmospheres. Please note that while the ATEX and IECEX certification system are similar, the North American approach is different; see area classification below.

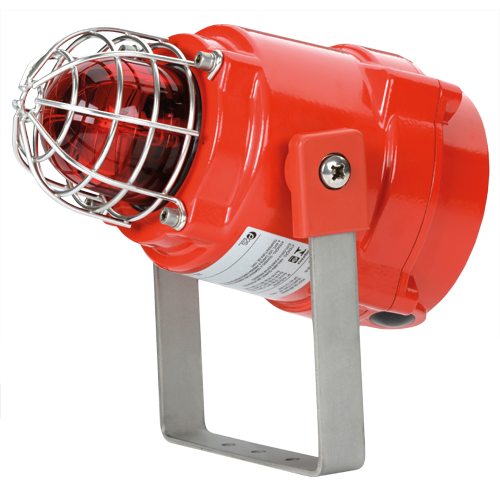

Example Ex d (explosion or flameproof) products from LGM:

Scope

ATEX certification of products for use in potentially hazardous atmospheres is compulsory.

Classification of equipment

The ATEX directive classifies equipment into groups and categories which are defined by the marking on the equipment – see “Product marking” below.

Classification of an area

Hazardous areas are divided into Zones (European and IECEX method) or Classes and Divisions (North American method) according to the likelihood of a potentially explosive atmosphere being present.

| European and IECEX classification | Definition of zone or division | North American classification |

|---|---|---|

| Zone 0 (gases) | An area in which an explosive mixture is continuously present or present for long periods | Class I Division 1 (gases) |

| Zone 20 (dusts) | Class II Division 1 (dusts) | |

| Zone 1 (gases) | An area in which an explosive mixture is likely to occur in normal operation | Class I Division 1 (gases) |

| Zone 21 (dusts) | Class II Division 1 (dusts) | |

| Zone 2 (gases) | An area in which an explosive mixture is not likely to occur in normal operation and if it occurs it will exist only for a short time | Class I Division 2 (gases) |

| Zone 22 (dusts) | Class II Division 2 (dusts) |

Intrinsically safe (Ex ia) products from LGM:

Product marking

The ATEX directive requires the product to be marked with the CE mark, the ‘EX’ mark and the

equipment coding as per table below.

| Heading | Mark | Use |

|---|---|---|

| Explosion proof |  | in accordance with the ATEX directive |

| Equipment Group | I | For use in underground mines |

| II | For use in all other places | |

| Category | 1 | Equipment that is intended for use in areas where an explosive atmosphere is present continuously, for long periods or frequently |

| 2 | Equipment that is intended for use in areas where an explosive atmosphere is likely to occur in normal operation and must ensure a high level of protection. | |

| 3 | Equipment that is intended for use in areas where an explosive atmosphere is unlikely to occur in normal operation and must ensure a normal level of protection. | |

| Gas / Dust | G | Equipment certified for use in flammable gases |

| D | Equipment certified for use where dust is present in the atmosphere | |

| Type of Protection* | d | Flameproof |

| Ia | Intrinsically Safe | |

| e | Increased safety | |

| Gas Group | I | Mines |

| II | Surface above ground industries | |

| Gas Sub Group | A | Less easily ignited gases e.g. propane |

| B | Easily ignited gases e.g ethylene | |

| C | Most easily ignited e.g. hydrogen or acetylene | |

| Temperature Classification Hazardous area apparatus is classified according to the maximum surface temperature produced under fault conditions at an ambient temperature of 40°C, or as otherwise specified. The standard classifications are as shown | T1 | 450ºC |

| T2 | 300ºC | |

| T3 | 200ºC | |

| T4 | 135ºC | |

| T5 | 100ºC | |

| T6 | 85ºC |

* There are 8 methods of protection, for simplicity we have listed the 3 most commonly used.

Product marking example

An ATEX approved electrical product is marked with the following code:

From the breakdown of the code below it can be seen that the product is flameproof,suitable for use in zone 1 surface applications where gas group B gases may be present and the surface temperature of the product under fault conditions will not exceed 135 ºC.

Note: This document is for information only and does not form part of any offer or contract. It cannot take into account all the possible circumstances of a particular installation; the ultimate responsibility for safety remains with the end user. Expert guidance should be sought before placing into service, maintaining or repairing any item of equipment in a potentially explosive atmosphere. If there is any doubt at all, seek specific expert advice on the particular problem.

Barrier products to support EX ia from LGM: